Greenhouse Gas Inventory and Energy Resource Management

Advantech adheres to the original devotion to the idea of being a global citizen, and to the corporate purpose of living a happy life. We are thus willing to contribute to environmental improvement and labor safety maintenance. Advantech has gone beyond introducing the ISO 14001 environmental management system in 1996 and the OHSAS 18001 occupational safety and health management system in 2005 (revised in 2020 to ISO 45001). In addition to complying with the relevant government environmental protection and regulations of the Occupational Safety and Health Act , we are also committed to reducing the impact on overall environmental safety and health in the greenhouse gas management, product design, product use, and disposal stages.

And through the participation and commitment of all employees, we can achieve the goal of environmental protection and sustainable development of the business. This scope covers Advantech’s main global operations and production factories, together accounting for 92.3% of total consolidated revenue.

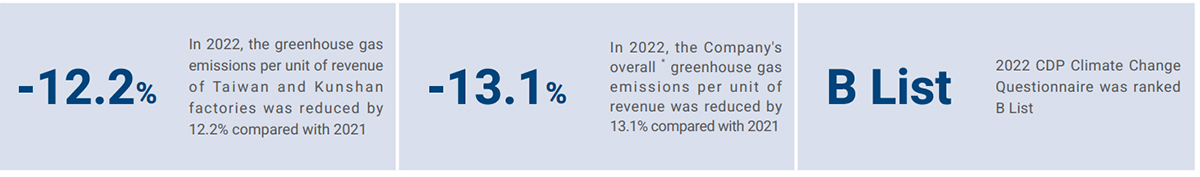

Highlighted Projects

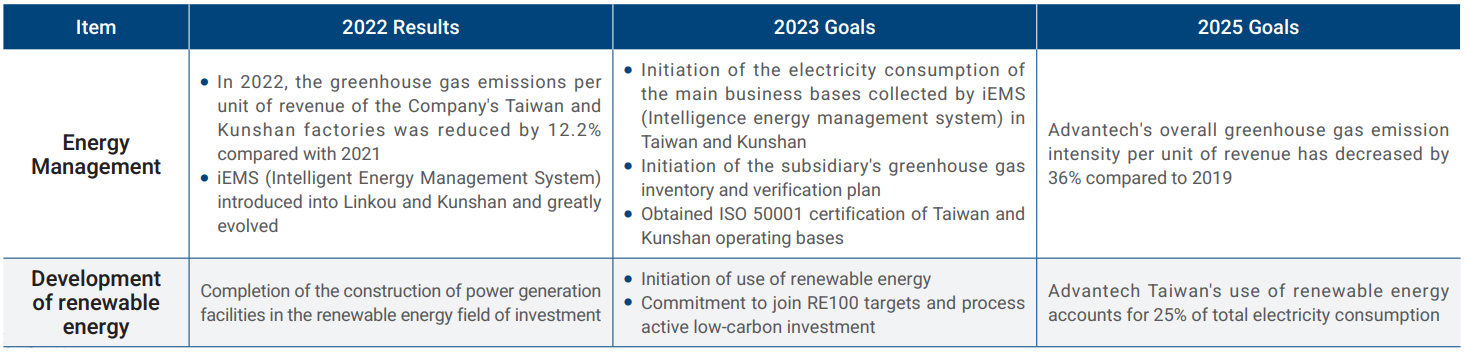

Phased Achievements and Future Goals of Greenhouse Gas Management

Greenhouse Gas Inventory and Management

Advantech is creating a low-carbon business environment. Based on Taiwan‘s Greenhouse Gas Reduction and Management Act, and on the quantification, monitoring, reporting and verification procedures for greenhouse gas inventory provided by the ISO 14064-1 standard, we established a Greenhouse Gas Inventory Promotion Committee in order to promote various tasks connected to greenhouse gas inventory and reduction. We have done so with a view of reducing direct and indirect greenhouse gas emissions year by year. In 2011, we also joined the Carbon Disclosure Project (CDP) and have disclosed the Company’s carbon reduction plans and performance annually.

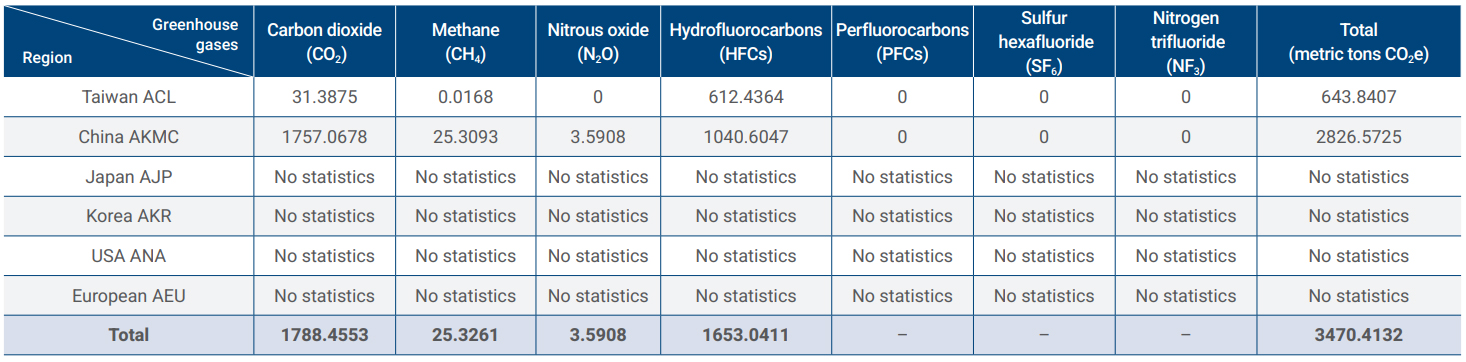

Greenhouse Gas Inventory

In recent years, Advantech has carried out greenhouse gas inventory, and the main operating bases and production factories that have been verified are Taiwan and Kunshan, China. In the future, major overseas operating bases and manufacturing areas will be gradually included. Advantech's Taiwan factories make reference to ISO 14064-1 and to the GHG Protocol Evaluator Tool in addition to requiring self-inspections. Furthermore, third party on-site inspections have been carried out by Taiwan SGS Limited starting from 2019. Organizational boundaries are drawn in reference to the requirements given by the ISO 14064-1:2018 standard.

Organizational boundaries are set with operational control rights; furthermore, we establish the Company's greenhouse gas inventory management procedures and inventory reports, and we redefine the emission source inventories. Organizational boundaries include Rueiguang Headquarters, Taipei Sunny Building, the Donghu Factory, and the Linkou Campus. In addition to the qualitative and quantitative inspections of Scope 1 (Category 1 direct GHG emissions) and Scope 2 (Category 2 indirect GHG emissions associated with energy production), the scope of inventory inspections also involves conducting inventory of emission source in Scope 3 (Categories 3, 4 and 5 indirect greenhouse gas emissions). In Scope 1, Advantech's Taiwan factories emitted a total of 643.8407 metric tons of CO2e.

Advantech's Kunshan factories conducted their first 2014 annual ISO14064-1 greenhouse gas emission inventory in 2015, and a third-party on-site inspection was conducted by the China Quality Certification Center (CQC). As a result of the 2022 inventory, it was found that Advantech's Kunshan region produced a total of 2,826.57 metric tons of CO2e in Scope 1. Emissions by region are shown in table.

Greenhouse Gas Scope 1 Emissions of Advantech's Main Global Operations and Production Factories in 2022

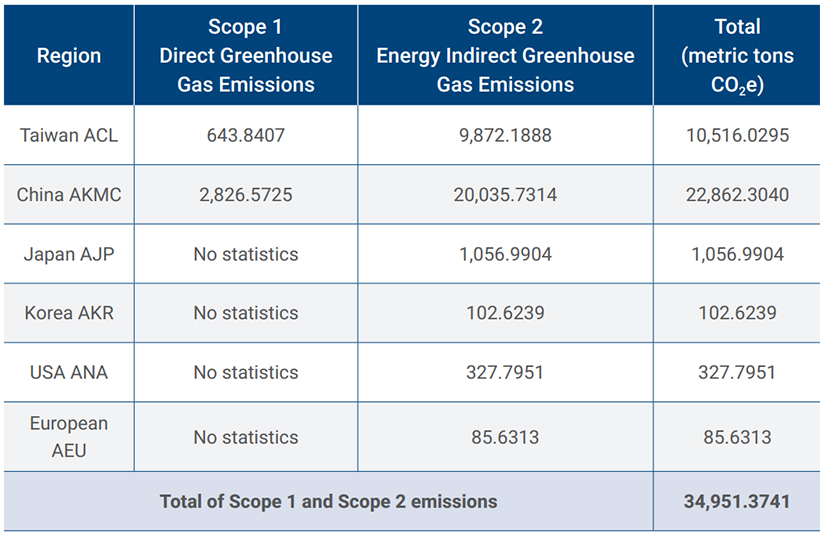

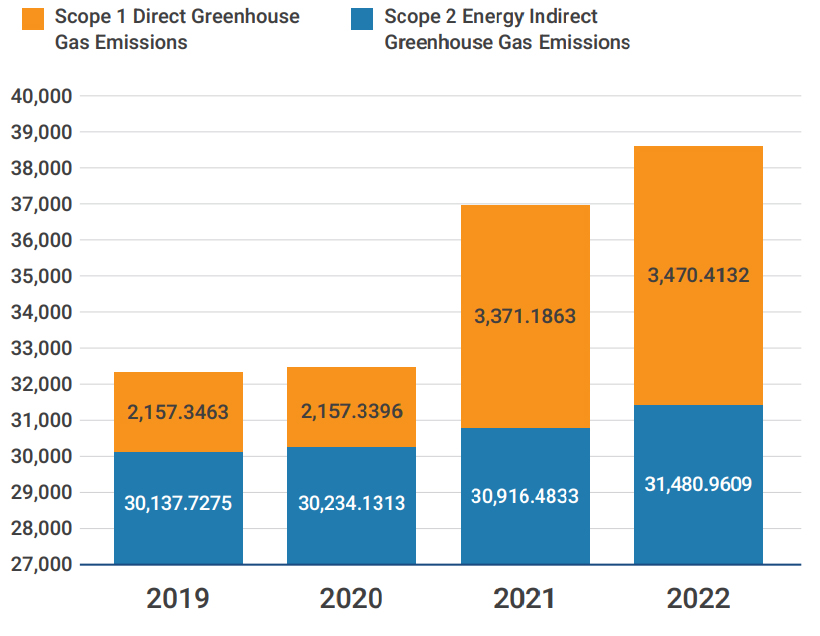

Among Advantech's Taiwan factories, Scope 2 only involve the use of purchased electricity. Carbon emissions are calculated based on the 2021 electricity factor of 0.509 kg CO2e announced by the Bureau of Energy of the Ministry of Economic Affairs, for a total of 9,872.1888 metric tons of CO2e. For Advantech's Kunshan factories, Scope 2 included the use of purchased electricity and purchased steam for a total of 20,035.73 metric tons of CO2e. Carbon emission calculation of electricity refers to the grid emission factor in ""the average carbon dioxide emission factor of China's regional power grid in 2011 and 2012."" The emission factor of East China regional power grid in 2012 is 0.7035 kgCO2e. Carbon emissions calculations for steam refer to an emission factor of 110 kg CO2/GJ for steam given in "Guidelines for Accounting Methods and Reporting of Greenhouse Gas Emissions of Enterprises in Other Industries." Among Advantech's Japan factories, Scope 2 emissions only involved the use of purchased electricity. Carbon emissions are calculated based on the electricity factor of 0.365 kg CO2e announced by Japan, for a total of 1,056.9904 metric tons of CO2e. Among Advantech's factories in Korea, America and Europe, Scope 2 emissions only also involved the use of purchased electricity. Carbon emissions are calculated based on the electricity factor of 0.4208 kg Co2e,2e, 0.3641 kg Co2e,2e, and 0.3665 kg CO2e by searching on the public website (Low Carbon Power), respectively. The greenhouse gas scope 1 and scope 2 emissions of Advantech's main global operations and production factories are shown in Table. The total emissions of Scope 1 and Scope 2 in 2022 was 34,951.3741 metric tons of CO2e. The greenhouse gas scope 1 and scope 2 emissions of Advantech's main global operations and production factories in recent years are shown in Figure.

Greenhouse Gas Scope 1 and Scope 2 Emissions of Advantech's Main Global Operations and Production Factories in 2022

Greenhouse gas inventories of factories in Japan, South Korea, the United States and Europe have not yet been verified by third party.

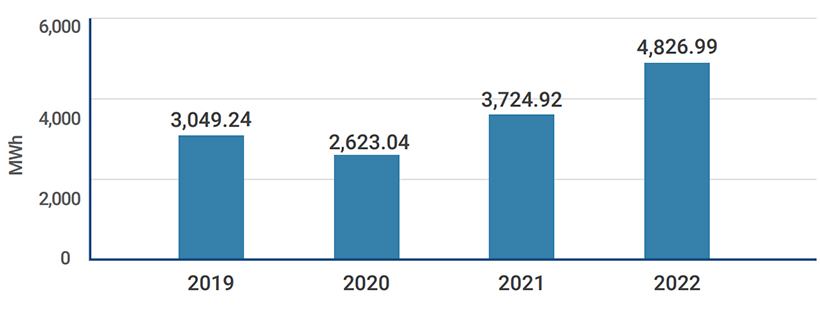

Scope 1 and Scope 2 greenhouse gas emissions of Advantech's main global operations and production factories in recent years

GHG Category 1 Emissions of Advantech’s Main Factories in 2021

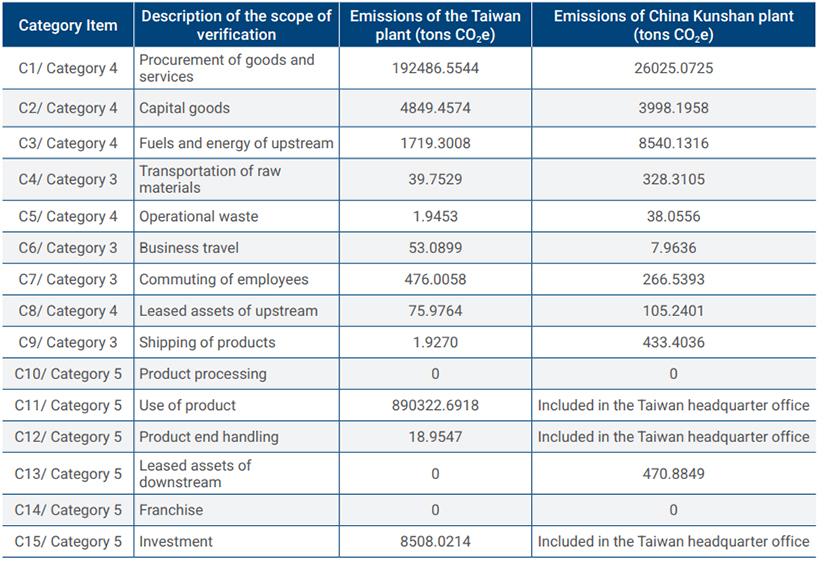

The average GHG emission per unit of turnover of Advantech's main operating bases and manufacturing factories in 2022 (Scope 1 and Scope 2) was 0.508 tons of CO2e per NT$1 million, which is 13.1% lower than the average GHG emission per unit of turnover in 2021 of 0.585 tons of CO2e per NT$1 million. The main reason is that Advantech achieved overall reduction in electricity consumption by integrating manufacturing systems in Linkou and Donghu factories, improving manufacturing efficiency and making good use of Linkou’s energy-saving systems. Meanwhile, the Advantech Kunshan Manufacturing Center has launched various energy-saving projects since 2019, including the establishment of an energysaving efficiency evaluation mechanism for each unit, energy-saving evaluation and verification of electrical machinery and equipment, and reduction of domestic electricity costs. In the future, we will continue to set an annual goal of reducing greenhouse gases per unit of turnover. In addition to achieving the goals set by the SBT announcement, this will also deeply embed the concept of energy saving in the hearts of colleagues and help it become an important part of the Company’s culture. In order to discover the key factors for climate change mitigation, Advantech Taiwan has also initiated inventories of other sources of GHG emissions in addition to emissions from its own operations. In 2019, the ISO14064-1 greenhouse gas emissions inventory was adopted to identify other types of GHGs along with relevant inventory methodologies being established. This was done with a view to identifying emission hotspots, setting reduction targets, and gradually implementing reduction measures. Please refer to Table for identification and emissions in Scope 3 for Advantech Taiwan and China-Kunshan in 2022.

1. ISO14064-1 -1:2006 Scope 3 C1~C15 corresponds to ISO14064-1:2018 Category 3~6.

2. The use of products and the disposal of products are the scope of the global inspection of Advantech.

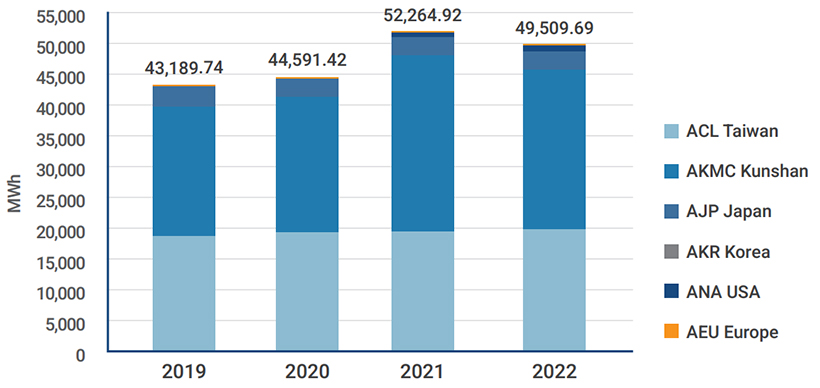

Energy Data Management

The main source of greenhouse gas emissions from Advantech's factories was carbon dioxide generated during the power generation process of the externally purchased electricity required for the Company's operations. This emission source accounted for more than 80% of the Company's overall emissions in 2022. In 2022, the total energy consumption (electricity, steam, gasoline, diesel, natural gas) in Advantech's main operating bases and manufacturing factories came to 223,340.35 GJ.

Electricity Consumption among Advantech’s Main Operations and Production Factories in Recent Years

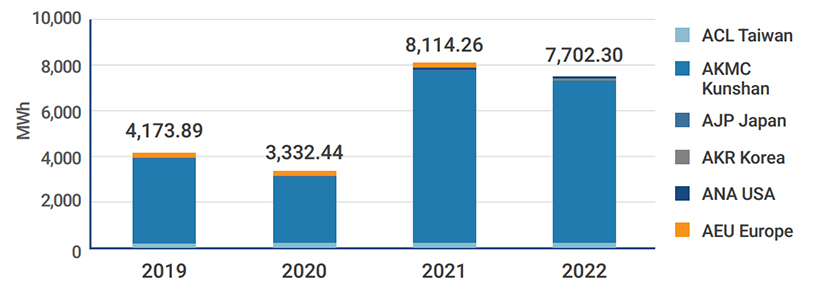

Energy consumption of non-renewable fuels in the Advantech plant (gasoline, diesel, natural gas, LPG)

Steam (Non-renewable) Energy Consumption of Advantech

Energy Management Action

Advantech's overall energy management strategy includes: daily energy savings, development of an iEMS building energy management system, and a clean energy strategy.

Try to replace in-person meetings with video conferencing

Prioritize the procurement of office equipment and information electronic products with energy-saving labels

Control indoor air temperatures

Encourage employees to turn off the lights

Energy-saving facilities in the office area

LED lamp replacement

Upgrades or replacement of air compressors, water chillers, and other equipment

Advantech is committed to developing an Intelligent Energy Management System (iEMS). We carry out energy-saving management in the two dimensions of management and operations, doing so through energy consumption information capture, data uploads to the cloud, AI analysis, information presentation, and realtime alarms; and via cooperation with scheduling adjustments, equipment cleaning, and maintenance, and the replacement of high-energy-consuming equipment. Advantech's iEMS was upgraded in mid-2020, and the platform was migrated to Advantech's WISE-Stack private cloud by the end of 2020. Officially launched in Linkou in the first quarter of 2021, the first wave of functions included an overview of energy saving performance used by top decision makers, real-time energy consumption monitoring, and abnormal energy consumption analysis for the use of managers, and so on. Furthermore, it was launched in the Kunshan Campus in the second half of 2021. In 2023, Xi'an, AESC (Eindhoven), ACL (Linkou, Ruiguang, Taipei Sunny) will be launched; in 2024, the second phase of iEMS Global Roll Out will be deployed in areas of AKR, ACN (ABJ), ACN (ASH), ACN (AKDC), ANA (Milpitas, Irvine, Ottwa), and AJP (Tokyo, Nogata) to expect the system layout to be used to check the carbon reduction. In addition, we make energy consumption information transparent and compare the use of energy consumption. Therefore, the energy saving management function is generated from top to bottom through Advantech's monthly energy consumption information in Linkou, Neihu, Kunshan, Shanghai, Xi'an, and Beijing through the eManager management system.

Solar power generation: The Linkou Campus is equipped with solar power panels, which have been in use since June 2019. In 2021, they generated about 48,489 kWh of electricity per month on average for use in parallel with Taipower. In addition, the new building in Linkou Phase 3 is also expected to be fully equipped with solar panels, with an estimated power generation capacity of 8,000 kWh per month. The Newcastle (Gaming Team) office in the UK has installed solar photovoltaic panels on the roof, which can generate up to 27,021 kWh/year, which is expected to start recording data in 2023. The New HQ phase-I facility (AASC-II) in the United States is also expected to set up solar power generation, which is estimated to generate 912,000 kWh/year.

Electricity purchases: The Company announced we would invest in renewable energy plants in 2021. First of all, 10 MW of our low-carbon investment solar power plant in southern Taiwan was supplied to the Taiwan factory, and it is expected to gradually start supplying power in 2024. The goal is that Taiwan and Kunshan, China will reach the goal of using 50% renewable energy by 2030, and Advantech's global renewable energy use will reach 100% by 2040. From 2023 onwards, the Kunshan Manufacturing Park in China will gradually achieve the RE100 goal through the procurement of green electricity.

Future Plans

Looking to the future, Advantech integrated the Taiwan factory and concentrated production in the Linkou Phase 2 Intelligent Factory. Furthermore, through the energy management system and production line optimization management mechanism, we will achieve energy consumption reduction targets and reduce electricity consumption to realize energy saving benefits. The Intelligent Energy Management System (iEMS) is also expected to complete the Global Roll Out project by 2024. Important overseas operating bases such as the United States, Europe, and Japan are also gradually planning solar power generation installations or suitable local renewable energy solutions.