Policy and Actions

Environmental Responsibility

In terms of environmental management, Advantech not only implements environmental protection work related to sewage and waste in accordance with relevant laws and regulations, but has also formulated an Environmental Safety and Health Management System Manual as a guiding principle for the operation of the management system, and regularly inspects and implements management. All sewage meets discharge standards and is reported as required. Business waste is also entrusted to be disposed of by qualified removal companies.

The Company's environmental declaration and environmental policy are as follows:

- 1. In our design and production of products and services to our customers, we are committed to the concept of green to reduce and prevent the generation of waste and pollution through the 3R (Reuse, Recycle, Reduce) as far as possible. Also committed to energy conservation, waste reduction, emission reduction, and circular economy to reduce the impact of products and production activities on the environment.

- 2. Evaluate the risk and opportunity to establish management program to promote energy conservation and reduce waste of resources in accordance with global climate change, environmental issues and international regulations and standards related to environmental protection, energy and resource efficiency.

- 3. Establish a green supply chain from design, production, delivery and service through the cooperation with customers, suppliers and outsourcing parties.

- 4. Ensure that all our activities comply with requirements of environmental, health, safety & HSF regulations and customers’ designation. Promote relevant environmental, health, safety & HSF protection knowledge and activities through education and training, so that all personnel may participate in achieving the objective of continuous improvement and zero disasters, occupational diseases and pollution.

- 5. Continuously promote improvement through the management system, deeply construct the corporate risk management culture for environment, safety, and health, strengthen the important responsibility and awareness of sustainable development with all employees, joint ventures and stakeholders. Also follow this policy due diligence when merging and acquiring related businesses.

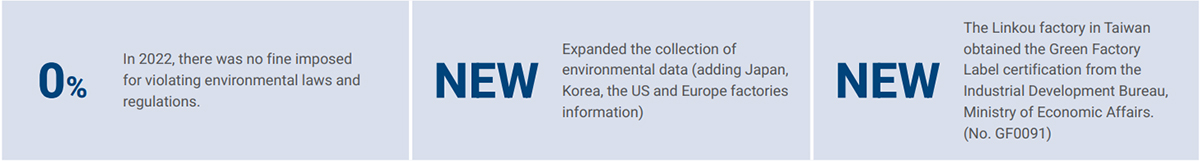

Highlighted Performance

Environmental Promotion Procedures and Actions

In order to achieve the promise of eco operation and sustainable development, the Company has established an environmental management system since 1996. We have done so in order to better implement the planning of environmental protection issues and to achieve the effectiveness of resource use. Meanwhi le , through our Environmental Safety and Health Committee, we have established Advantech's environmental safety and health conceptual framework, advocated energy conservation, improved energy efficiency, and listed energy cost reduction as an annual key audit item.

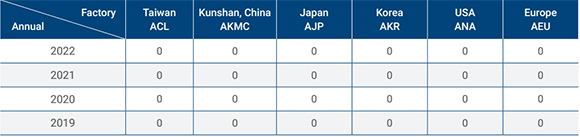

Furthermore, we regularly review performance through our environmental management system and GHG inventory. The table shows the environmental management system and greenhouse gas inspection and certification of each factory region of Advantech. This chapter’s writing scope covers Advantech’s main global operations and production factories, together accounting for 92.3% of total consolidated revenue. There was no environmental violations in 2022. The environmental violations at Advantech’s main global operations and production factories in the past four years are summarized in tables.

-

Environment-related certification of Advantech’s main global operations and production factories

-

Statistics on Environmental Violations at Advantech’s main global operations and production factories

Advantech's Environmental Resources Inputs and Outputs (Scopes for Factories in Taiwan, Kunshan (China), Japan, Korea, USA, and Europe)

Energy and Resource Use and Waste Management

Water Use and Management

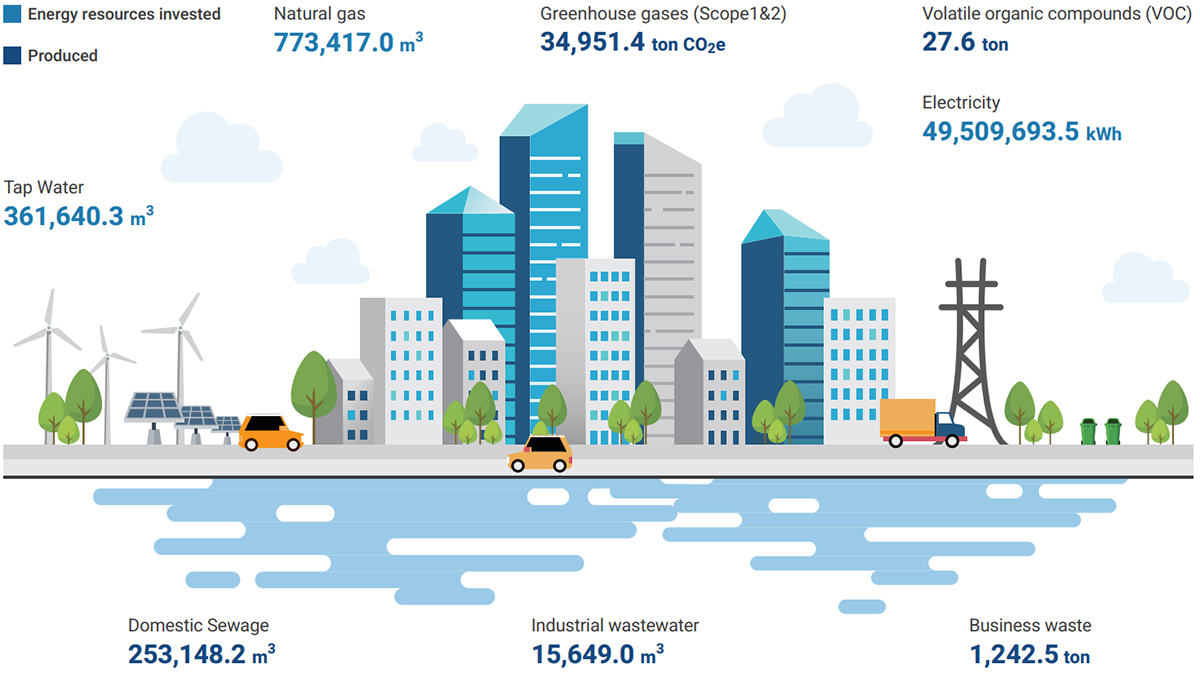

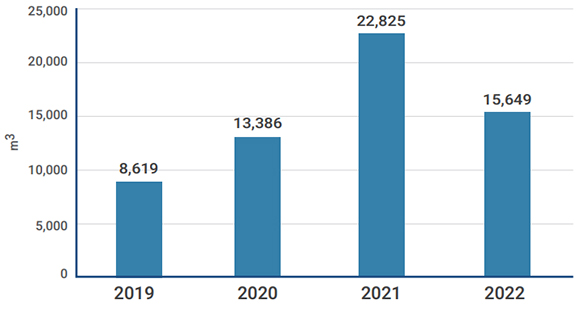

Advantech's factories use water-saving faucets and toilets and promote water-saving measures in order to find ways to reduce water consumption per person. All factories are located in developed industrial areas or campuses in metropolitan areas. In terms of tap water supply, there is no extraction of groundwater or well water. The total water consumption of Advantech’s global main operating locations and production factories in the past four years is shown in Figure 4.4.1. To further analyze of the increase in total water consumption of revenue in 2021 and 2022, it is because of the expansion of the scope of disclosure to include information on overseas factories in addition to the expansion and operation of the Kunshan Factory (Phase 5).

Advantech has successively implemented water-saving improvement plans in recent years. In Taiwan, water-saving solutions such as rainwater recycling and reuse are mainly used for domestic water, intelligent irrigation water saving, and intelligent airconditioning cooling water and chilled water system monitoring and control. In 2022, the water consumption was saved for about 9,800 tons of water compared with 2021. The Kunshan factory area has installed water meters in the production workshops of each factory and conducted water metering management. This distinguishes water used for Phase 1, Phase 2, Phase 3, 4, and 5, dormitories, kitchens, and equipment, analyzing reasonable water consumption. In addition, water quality has been improved in the manufacturing process, and a total of 6,900 tons of water was saved in 2022. The main water-saving measures in the US factory are the installation of low-flow toilets and faucets, and leak detection and maintenance programs are carried out on a regular basis.

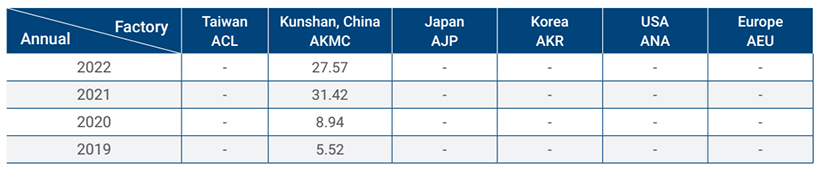

In the future, more improvement plans will be planned to save water resources. Except for Kunshan, China, which contains industrial wastewater discharge, Advantech's other factories do not discharge industrial wastewater. The amount of water discharged by the Kunshan factory in the past four years is shown in Figure 4.4.2. The Kunshan factory has been introduced reclaimed water reuse and overflow water reuse plans since 2022. The waste water in the process is recycled and reused to reduce the discharge of waste water. As a result, waste water consumption was reduced by 31% compared to 2021.

-

Water Consumption among Advantech’s Main Global Operations and Production Factories in Recent Years

*Note: No statistics on water consumption in 2019, 2020, and 2021 for Korea; No statistics on water consumption in 2019 and 2020 for the United States.

*Note: No statistics on water consumption in 2019, 2020, and 2021 for Korea; No statistics on water consumption in 2019 and 2020 for the United States. -

Advantech’s global industrial wastewater discharge volume in major operating locations and production plants in recent years

*Note: Only the factory in Kunshan, China, contains industrial wastewater discharged among Advantech's main operations and production factories.

*Note: Only the factory in Kunshan, China, contains industrial wastewater discharged among Advantech's main operations and production factories.

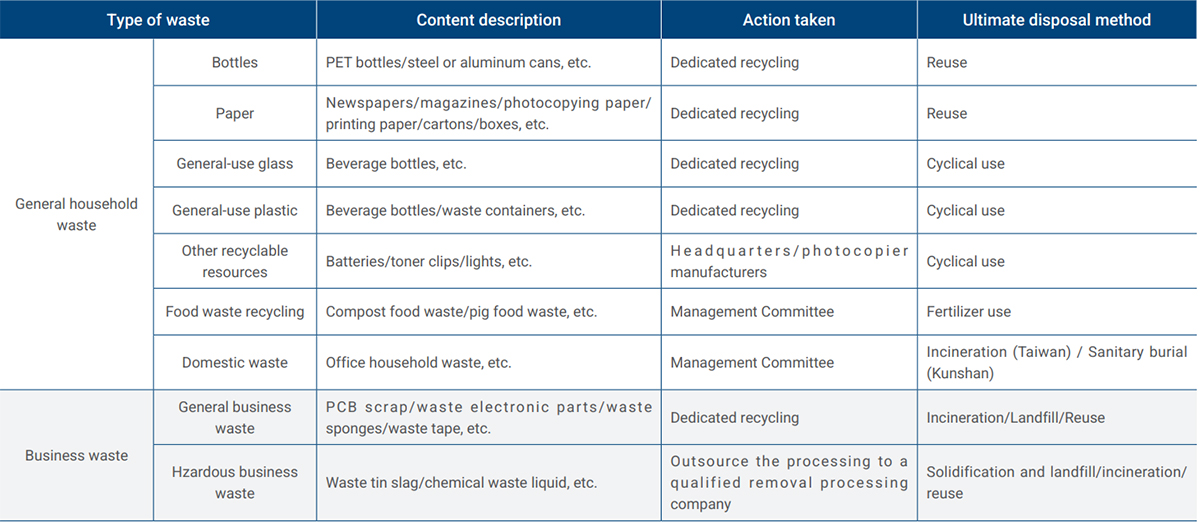

Waste Management and Resource Recycling Management

Zero waste is the ultimate goal of Advantech's waste management. We take total waste reduction and waste recycling as a strategy in addition to reducing waste output and achieving waste reduction through source management measures such as reduction of raw materials. Advantech also actively promotes the recycling of waste, such as reusing packaging materials to replace the existing end-of-pipe treatment model, and turning waste into useful resources. This not only truly achieves resource recycling, but also reduces energy consumption and waste disposal costs. Advantech devotes attention to its waste contractors every year. If a contractor breaches the contract or violates government regulations, it will undertake corresponding disposal or guidance or replacement. In 2022, Advantech did not have any major breach of contract or violation of laws by waste contractors. The Company's waste management model is shown in table.

Advantech Waste Management Model

Regarding the final disposal weights of waste at Advantech's main global operations and production factories, because the weight of domestic waste is an approximate estimate of the contracted clearance, weight information for further disposal classifications is not yet available. Therefore, only information waste is disclosed

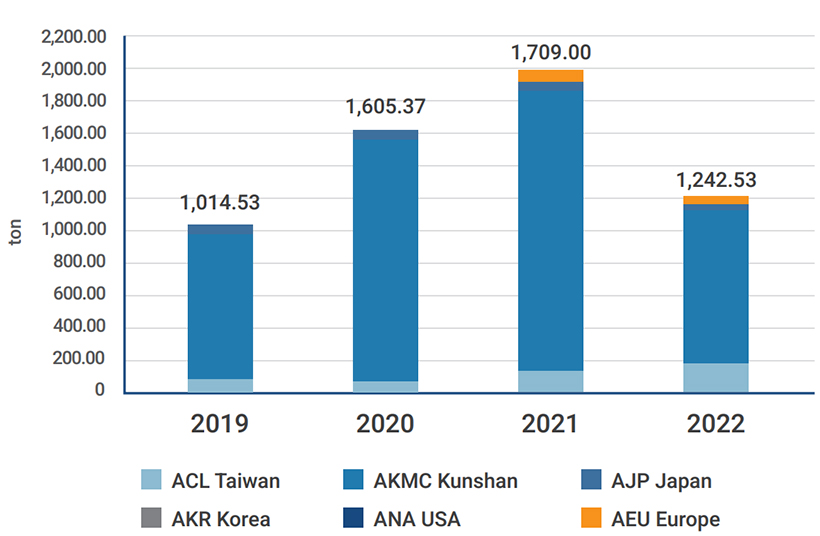

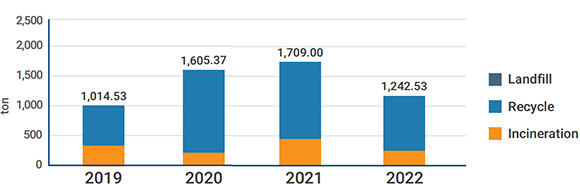

Figure:Disposal Volume of Business Waste among dvantech’s Main Global Operations and Production Factories in Recent Years

1. The source of statistics on the weight of waste in the Taiwan and Kunshan factories is the data reported by each factory to the competent authorities. The source of waste statistics in Japan, the United States, and European factories is the data of outsourced processing.

2. No statistics on the production volume from 2019 to 2022 for Korea.

3. The production volume for the United States and Europe in 2019 and 2020 was not counted

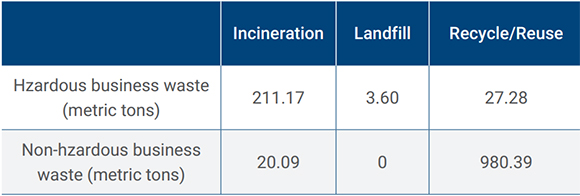

According to the statistics, the total waste disposal volume of Advantech’s main operating bases and production regions in 2022 was 1,242.53 metric tons. Out of this, there was 1,000.48 metric tons (80.5%) of non-hazardous waste and 242.05 metric tons (19.5%) of hazardous waste.

-

Waste Disposal Methods of Advantech's Main Global Operations and Production Factories in 2022

*Note:

*Note:

1. The source of statistics on the weight of waste in the Taiwan and Kunshan factories is the data reported by each factory to the competent authorities. The source of waste statistics in Japan, the United States, and European factories is the data of outsourced processing.

2. The production volume of Korea in 2022 was not counted. -

Business Waste Disposal Status among Advantech's Main Global Operations and Production Factories in Recent Years

*Note:

*Note:

1. The source of statistics on the weight of waste in the Taiwan and Kunshan factories is the data reported by each factory to the competent authorities. The source of waste statistics in Japan, the United States, and European factories is the data of outsourced processing.

2. No statistics on the production volume from 2019 to 2022 for Korea.

3. The production volume for the United States and Europe in 2019 and 2020 was not counted.

Air Pollutant Management

Air pollutants have become one of the important environmental issues of global concern. In 2017, the International Agency for Research on Cancer (IARC) listed air pollutants as known primary human carcinogens. Volatile organic compounds (VOCs) are one of the most important portions of air pollutants that are harmful to ecology and health. Advantech also cares about the effectiveness of air pollution controls and about atmospheric air quality. Volatile organic compounds is one of the important sources of contribution to the formation of PM2.5 and so fine that it penetrates into the lungs very easily; thus, the impact of VOCs on human health cannot be ignored. Regarding air pollution data and information disclosures, Advantech has put together three key points:

Advantech's production process does not generate ozone-depleting substances (ODS) and hence there are no ODS emissions.

Advantech Taiwan and Advantech Japan mainly utilize assembly processes with low air pollution load, so there is no emission of nitrogen oxides, sulfur oxides, or volatile organic compounds (VOCs).

Advantech's Kunshan (China) Campus utilizes liquid coating and powder coating processes, and the volatile organic compounds (VOCs) emitted are all in compliance with local regulations

Volatile Organic Compounds (VOCs) Emitted by Advantech’s Main Global Operations and Production Factories in Recent Years (Unit: mt)

In order to implement environmental reduction targets, Advantech Kunshan (China) has adopted effective control of volatile organic compounds (VOCs). This has been accomplished through online real-time continuous monitoring and outsourced monitoring and management of emissions, and improvements in equipment processing efficiency to reduce environmental emissions. Improvement projects have been implemented successively in recent years, for example, the transformation of process technology, changing the liquid baking varnish to powder baking varnish waste gas and improving the equipment treatment efficiency of the production line, effectively reducing the generation of energy, waste gas and VOCs. In 2022, the production of VOCs was reduced by 12% compared with 2021.

Biodiversity and Conservation of Forests

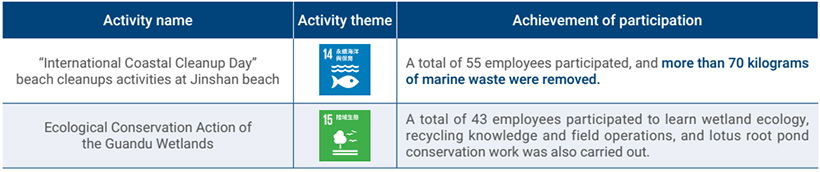

Advantech started to focus on the topics of biodiversity and conservation of forests in 2022. Moreover, we joined the Taiwan Nature Positive Initiative (TNPI) initiated by the Taiwan Business Council for Sustainable Development (BCSD-Taiwan). We take more active actions on this issue to increase Advantech's corporate resilience. Moreover, Advantech's IoT expertise is being applied to empower nature conservation.

Progress in 2022

In 2022, Advantech handled the following activities related to biodiversity and conservation of forests. Advantech’s headquarter and major overseas business units have jointly promoted and implemented the green office plan. It emphasizes and encourages the paperless work, the use of double-sided printing of office paper, the paper recycling and reuse, and the promotion of office paper and household paper to choose FSC (Forest Stewardship Council) certified sustainable forest paper or other papers made through recycling.

Plans for 2023

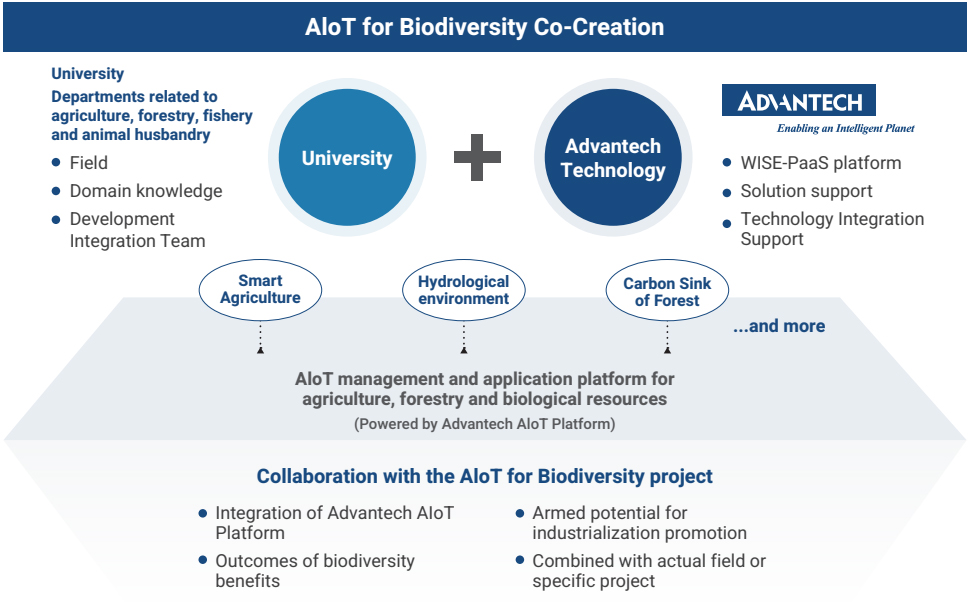

AIoT for BiodiversityFor 2023, Advantech has drawn up plans related to biodiversity and conservation of forests as follows: In 2023, it is estimated that NT$3 million will be invested in co-creating AIoT for Biodiversity innovative solutions in the form of industry-university cooperation. One of the main axes of the project will be real-time monitoring of biodiversity and identification of species assisted by artificial intelligence. The AIoT platform is used to integrate technologies such as image and audio recognition. Databases of herbivores and birds of the forest are created for specific fields. There are also observation of the impact of human activities (newly planted forest roads and tourist activities) on it. Under the longterm large-scale introduction, this AIoT platform and data will help the Forestry Administration to grasp the ecosystem and changes of forest land. AIoT observation data is applied to plan and make decisions that minimize ecological impact. We apply our own core competence - the energy of the AIoT platform, and jointly develop innovative solutions with external experts and partners to establish a demonstration field. The biodiversity benefits of this plan have been verified in the field in the short term, and it is expected to be replicated and promoted in the industry in the future.

Coastal Forest Restoration

In cooperation with Tse-Xin Organic Agriculture Foundation, we adopted 102 trees in the afforestation site in Shalun, Taoyuan, and maintained them for three consecutive years. The damage caused by the strong northeast monsoon, flying sand, sea tide, and salinity to the vegetation in this area has been slowed down through the afforestation of the first-line coastal forests. In this way, the coastline can be protected and intact habitats for native organisms are provided.

Wetland Conservation

In cooperation with Guandu Natural Park, 5 hectares of paddy fields and wetlands in the Guandu Plain were adopted. The environment and biodiversity are maintained through the cleaning and dredging of irrigation and drainage ditches, the waterways are guaranteed to be unobstructed, siltation is reduced, flood water storage space is provided, and the pressure of wetland terrestrialization is reduced.

Please refer to the full text of the official announcement for Commitment related to Advantech Biodiversity and No Deforestation